RELIABILITY YOU CAN TRUST

The high current PLD drivers couple the high-reliability architecture of Wavelength Electronics’ lower-current PLD Series with a robust high-current output stage. Tens of thousands of PLD drivers are deployed in laser systems around the world, proving beyond doubt the reliability and stability of the design. PLD Series laser power supplies are found in fiber laser pumping, materials processing, pyrotechnic ignition, industrial welding and cutting applications, and laser diode LIV testers. It is CE certified. A PDF version of the Declaration of Conformance is available.

SELECTION OF DRIVE CURRENT RANGES

The PLD10000 drives up to 10 A, and the PLD12500 drives up to 12.5 A. With a compliance voltage capability of 27.5 volts, these PLD drivers are ideal for driving laser bars and stacks for high-power industrial applications.

These drivers are not recommended for low noise applications. See the LD10CHA, or LD15CHA for lower noise laser drivers.

Lower-current drivers are offered in the PLD Series, available in SIP PCB-mounted models at 200 mA, 500 mA, 1.25 A, 5 A, and 6.5 A output.

DESIGNED FOR EASY INTEGRATION

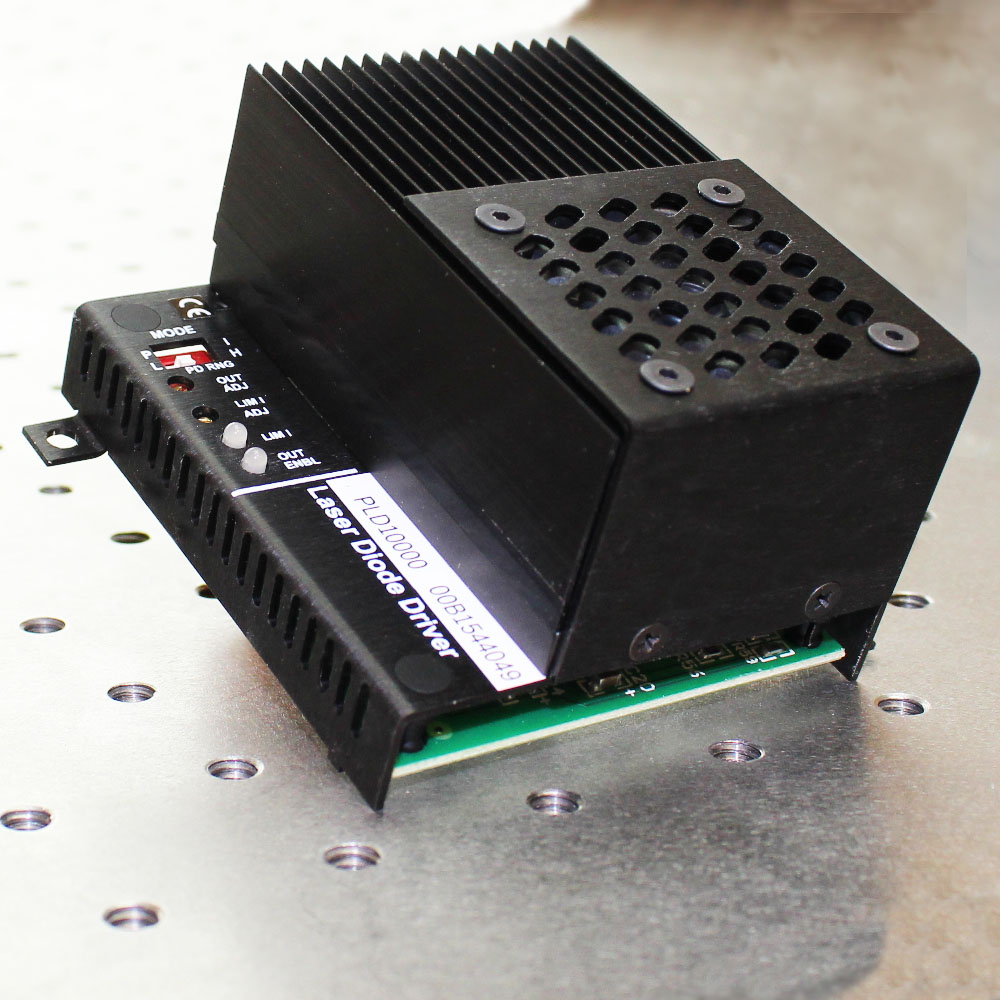

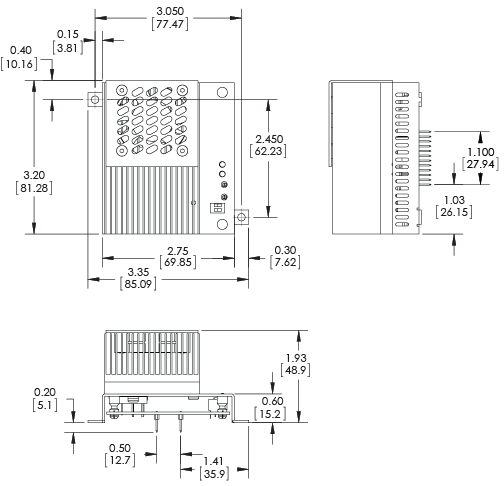

The high-current PLD is a DIP PCB-mounted package. The compact heatsink and fan are integrated and shrouded to optimize thermal performance with the smallest possible footprint. The PLD10000 can operate from a single 5 V power supply, while the PLD12500 requires two supplies. To accommodate high compliance lasers the PLD10000 can be driven from a separate power supply up to 30 V.

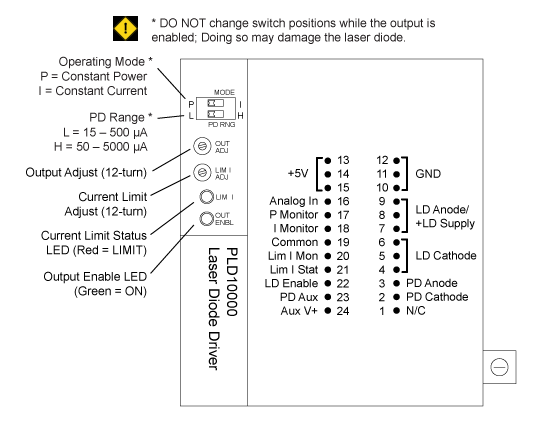

The PLD drivers operate in Constant Current mode, or, with photodiode feedback, Constant Power mode can be used to maintain a highly stable optical output level. Two photodiode ranges provide variable sensitivities, and excellent output stability is maintained whether operating in constant current or constant power mode.

The available PLD10EV evaluation circuit board reduces your development costs and allows you to focus on designing the features that will set your system apart.

PRACTICAL FEATURES, ROBUST DESIGN

Thoughtfully designed features provide valuable benefits and protect the laser against operational anomalies:

- If the drive current reaches the user-set limit, the latching current limit circuit switches off the laser drive current until the safety circuit is actively reset.

- Remote enable can be tied to a safety interlock and a temperature controller, such as Wavelength’s PTC Series.

- Built-in constant current and constant power operating modes minimize your electronics overhead.

- On-board controls allow quick and easy driver setup.

- Analog setpoint input gives you remote external control of the laser current and modulation.

- Available evaluation board speeds system design and prototyping efforts.

VALUABLE LASER SAFETY FEATURES

Built-in safety features make your product more robust to real world operating conditions: latching current limit, slow start circuit, and a mechanical shorting relay protect the laser and ensure long-term system reliability. Long-term reliability means better up-time, fewer service calls, and more customers who are satisfied with your products.

SERVICE AND SUPPORT

Download the brochure to view a more detailed specification chart, and then call Wavelength’s sales engineers so we can help you choose the right driver for your application.

Free, effective, and responsive technical support is available to simplify integration of Wavelength products into your OEM design. Standard product can be easily modified to meet your application requirements.