Electronic Manufacturing Services Capabilities

Our advanced manufacturing facility and well-qualified engineers allow us to provide full-service product manufacturing with JIT-dependability, flexibility, and world-class quality.

Process Design for Optimal Cost, Yield, and Delivery:

- Design for Manufacturability Evaluation and Process Plan is included in initial assessment

- Technical Program Management

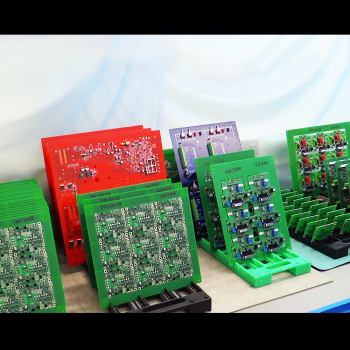

Printed Circuit Boards (PCBs):

- Single- and Double-Sided Assembly

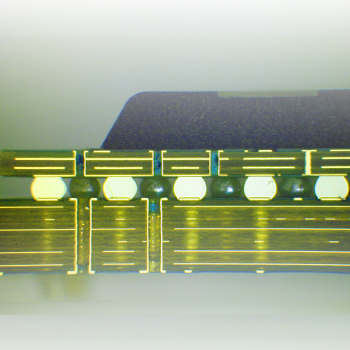

- Surface-Mount (SMT), Through-Hole, and Mixed Technologies

- Ball Grid Array (BGA) to 0.4mm pitch, and 0402 Packaged Components

- RoHS-compliant or Leaded

- Aqueous Wash or No-Clean Processes

- Two SMT Lines

- Selective Solder Machine for Plate-Through Automation

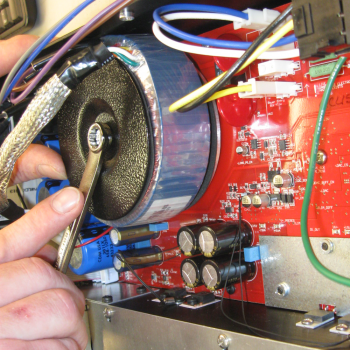

Electro-Mechanical Assembly:

- Box Build

- Cable Harness / Routing

- Heatsink Assembly

- Conformal Coat or Potting

Test & Troubleshoot:

Test to your protocol to ensure 100% accurate build

Quality Assurance Processes ensure builds are accurate and repeatable:

- Workmanship Standards to IPC Class 2 or 3

- Documentation Management of Bill of Materials and Assembly

- Instructions

- Moisture Sensitive Parts Handling

- Electro-Static Discharge (ESD) Prevention

- Parts Sourcing ensures only approved parts are used

- Visual Inspections throughout the build

Purchasing and Inventory Management:

- Turnkey Component Sourcing — from your BOM and approved supplier list

- Component Cost Reduction

- End-of-Life and Obsolescence Notification and Resolution

Logistics

Automated Shipping Systems for FedEx and UPS