Introducing Power Supplies

Power is the backbone of any electronic system and the power supply is what feeds the system. Choosing the right supply can be the critical difference between a device working at optimum levels and one that may deliver inconsistent results.

In addition to alternating current (AC) to direct current (DC) power supplies, DC to DC converters are also available. If DC is already available in your system, a DC to DC converter may be the better design choice than AC discussed below.

Direct current power supplies are either unregulated or regulated. Regulated supplies come in several options including linear, switched and battery-based.

AC-DC Conversion Basics

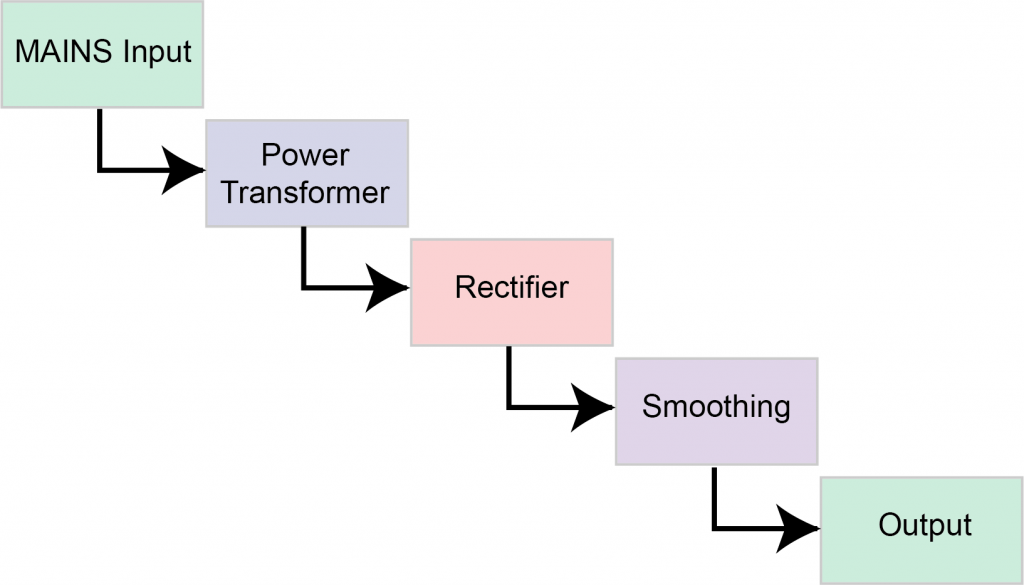

A power supply takes the AC from the wall outlet, converts it to unregulated DC, and reduces the voltage using an input power transformer, typically stepping it down to the voltage required by the load. For safety reasons, the transformer also separates the output power supply from the mains input.

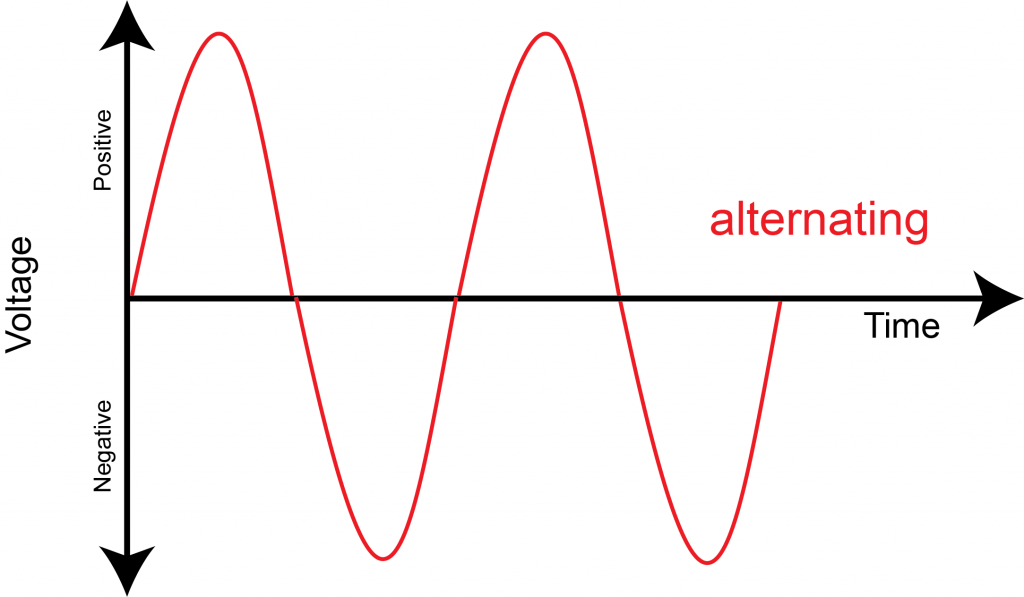

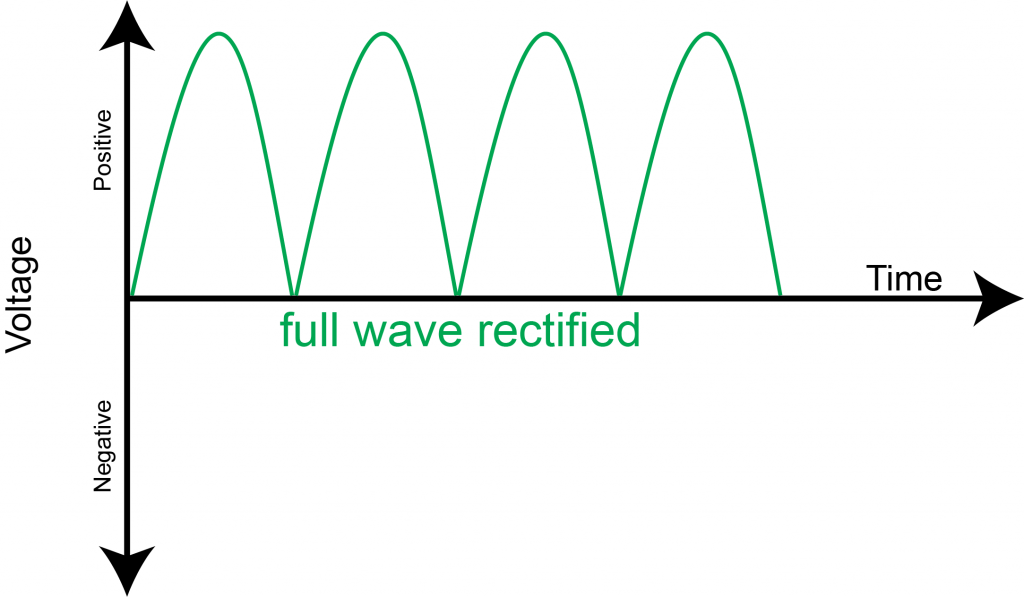

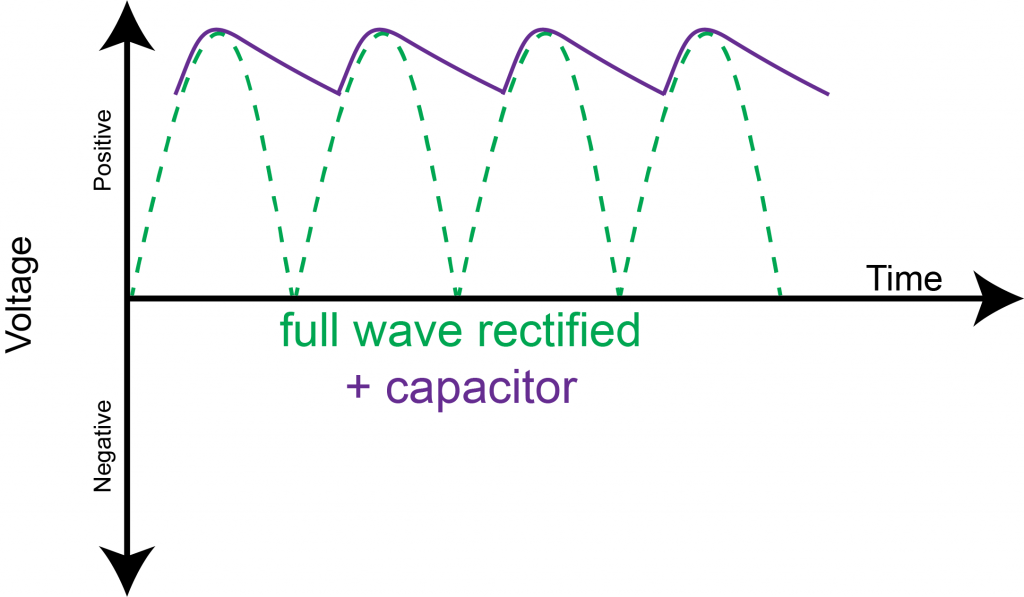

Figure 1, Figure 2, and Figure 3 illustrate the general transformation from AC to DC.

Alternating current takes the form of a sinusoidal wave with the voltage alternating from positive to negative over time.

Figure 1: Alternating Current from Wall Outlet

In the first step of the process, the voltage is rectified using a set of diodes. Rectification transforms the sinusoidal AC. The rectifier converts the sine waves into a series of positive peaks.

Figure 2: Full Wave Rectified

Once the voltage has been rectified, there is still fluctuation in the waveform—the time between the peaks—that needs to be removed. The rectified AC voltage is then filtered or “smoothed” with a capacitor.

The capacitor is typically quite large and creates a reservoir of energy that is applied to the load when the rectified voltage drops. The incoming energy is stored in the capacitor on the rising edge and expended when the voltage falls. This significantly reduces the amount of voltage droop and smooths out the voltage. Increasing the storage capacity of the capacitor generally produces a higher quality power supply.

Figure 3 shows the rectified voltage and how the capacitor smooths the droop.

Figure 3: Full Wave Rectified + Capacitor

Once the voltage conversion is complete, there is still some variation in output, called ripple. In a regulated power supply, the voltage is then passed through a regulator to create a fixed DC output with less ripple.

Power Supply Comparisons

AC power supplies come in two varieties, unregulated and regulated. Unregulated is the most basic type of power supply and does not have the ability to supply consistent voltage to a load, while regulated power supplies do and have many different design options.

Linear converters are the least complex but also create the most heat, while switched converters are more intricate and cooler but create more noise. Batteries are typically switched converters. Each has advantages and drawbacks but which to use will be based mostly on the type of application and the conditions under which it will be run.

Table 1 illustrates how the types of power supplies are categorized and summarizes many of the pros and cons of each type.

| UNREGULATED | REGULATED | ||

|---|---|---|---|

Pro:

Con:

|

Pro:

Con:

|

||

| LINEAR | SWITCHED | BATTERY | |

Pro:

Con:

|

Pro:

Con:

|

Pro:

Con:

|

|

Table 1: Types of Power Supplies

AC-DC Fundamentals

Alternating current is generated by electrons flowing in alternating directions. Direct current is generated by electrons flowing in only one direction.

AC is also called mains electricity, household current, domestic power, line power, or wall power because it is the voltage supplied by a wall outlet. Worldwide, AC voltages range from 100 to 240 V. The rate of direction change is typically 50 to 60 times per second and is designated as Hertz (Hz). The two most common frequencies are 50 Hz and 60 Hz.

The equipment designed to use AC tends to require large amounts of voltage, so the voltage is not stepped down as frequently as equipment using DC.

DC allows for a constant flow of current to a device. Because AC is delivered initially, power must first be converted from AC to DC.

Most smaller electronic devices (such as computers) require direct current to operate with an AC-to-DC converter from wall power. Alternating current is used for equipment that have motors (refrigerators are an example). Which type of current to use depends on the load being powered.

CAUTION: WHILE BOTH AC AND DC CAN SHOCK YOU, AC IS BY FAR THE GREATER RISK BECAUSE THE CURRENT CAPACITY IS SO MUCH GREATER. BE SURE THAT ALL ELECTRICAL EQUIPMENT THAT ACCESSES THE AC MAINS HAS A GROUND FAULT CIRCUIT INTERRUPTER (GFCI) IN USE.

Unregulated Power Supply Theory

Because unregulated power supplies do not have voltage regulators built into them, they typically are designed to produce a specific voltage at a specific maximum output load current. These are typically the block wall chargers that turn AC into a small trickle of DC and are often used to power devices such as household electronics. They are the most common power adapters and are nicknamed a “wall wart”.

The DC voltage output is dependent on an internal voltage reduction transformer and should be matched as closely as possible to the current required by the load. Typically the output voltage will decrease as the current output to the load increases.

With an unregulated DC power supply, the voltage output varies with the size of the load. It typically consists of a rectifier and capacitor smoothing, but no regulation to steady the voltage. It may have safety circuits and would be best for applications that do not require precision.

Figure 4: Block Diagram — Unregulated Linear Supply

The advantages of unregulated power supplies are that they are durable and can be inexpensive. They are best used, however, when precision is not a requirement. They have a residual ripple similar to that shown in Figure 3.

NOTE: Wavelength does not recommend using unregulated power supplies with any of our products.

Regulated Power Supply Theory

A regulated DC power supply is essentially an unregulated power supply with the addition of a voltage regulator. This allows the voltage to stay stable regardless of the amount of current consumed by the load, provided the predefined limits are not exceeded.

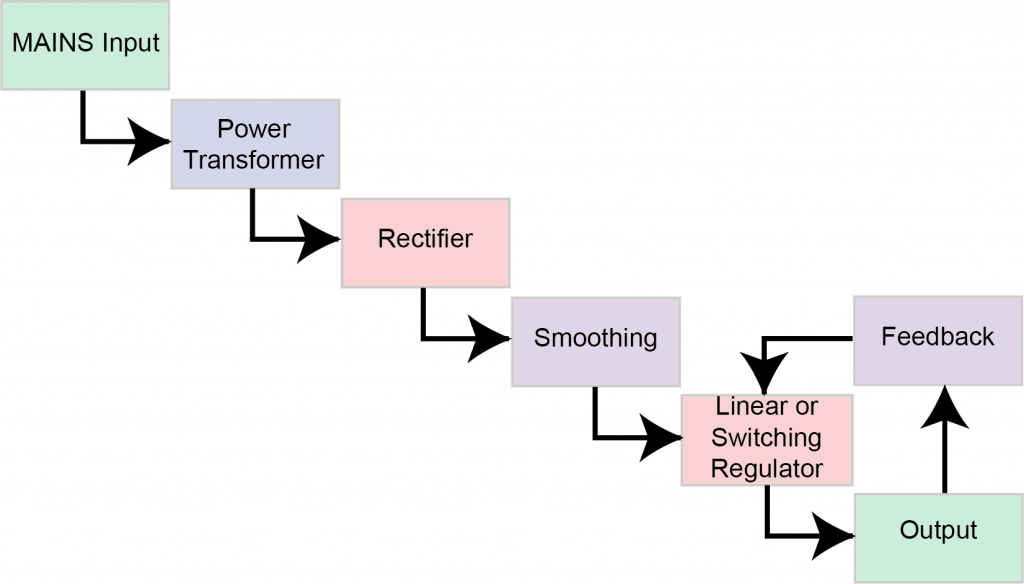

Figure 5: Block Diagram — Regulated Supply

In regulated power supplies, a circuit continually samples a portion of the output voltage and adjusts the system to keep the output voltage at the required value. In many cases, additional circuitry is included to provide current or voltage limits, noise filtering, and output adjustments.

Linear, Switched, or Battery-based?

There are three subsets of regulated power supplies: linear, switched, and battery-based. Of the three basic regulated power supply designs, linear is the least complicated system, but switched and battery power have their advantages.

Linear Power Supply

Linear power supplies are used when precise regulation and the removal of noise is most important. While they are not the most efficient power source, they provide the best performance. The name is derived from the fact that they do not use a switch to regulate the voltage output.

Linear power supplies have been available for years and their use is widespread and reliable. They are also relatively noise-free and commercially available. The disadvantage to linear power supplies is that they require larger components, hence are larger and dissipate more heat than switched power supplies. Compared to switched power supplies and batteries, they are also less efficient, sometimes exhibiting only 50% efficiency.

Switched Power Supply

Switched mode power supplies (SMPS) are more complicated to construct but have greater versatility in polarity and, if designed properly, can have an efficiency of 80% or more. Although they have more components, they are smaller and less expensive than linear power supplies.

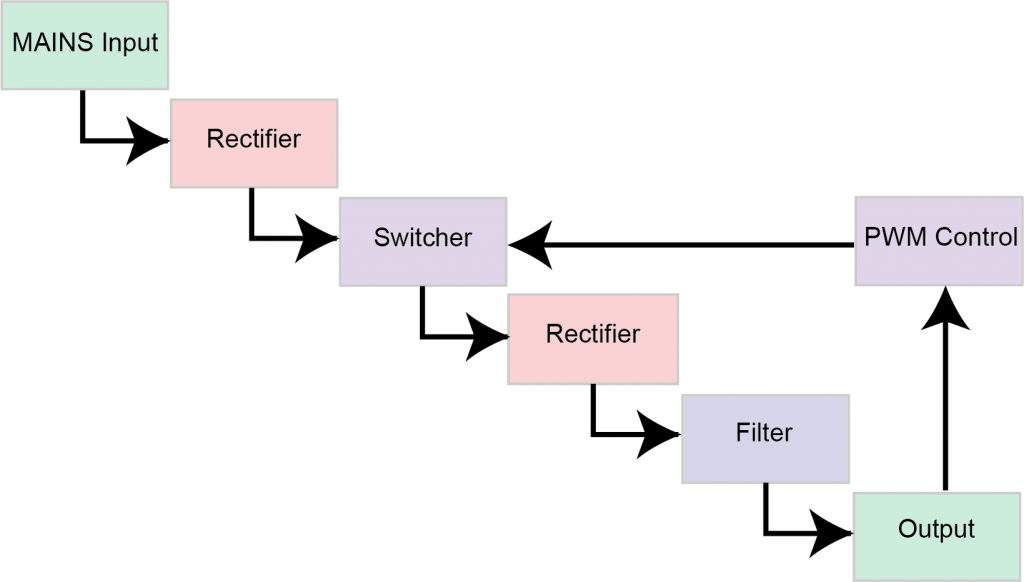

Figure 6: Block Diagram — Regulated Switching Supply

One of the advantages of switched mode is that there is a smaller loss across the switch. Because SMPS operate at higher frequencies, they can radiate noise and interfere with other circuits. Interference suppression measures, such as shielding and following layout protocols, must be taken.

The advantages of a switched power supply is that they are typically small and lightweight, have a wide input voltage range and a higher output range, and are much more efficient than a linear supply. However, a SMPS has complex circuitry, can pollute the AC mains, is noisier, and operates at high frequencies requiring interference mitigation.

Battery-based

Battery-based power is a third type of power supply and is essentially a mobile energy storage unit. Battery-based power produces negligible noise to interfere with electronics, but loses capacity and does not provide constant voltage as the batteries drain. In most applications using laser diodes, batteries are the least efficient method of powering the equipment. Most batteries are difficult to match the correct voltage to the load. Using a battery that can exceed the internal power dissipation of the driver or controller can damage your device.

Selecting a Power Supply

- When choosing a power supply, there are several requirements that need to be considered.

- The power requirements of the load or circuit, including

- voltage

- current

- Safety features such as voltage and current limits to protect the load.

- Physical size and efficiency.

- Noise immunity of the system.

Current Overload Warning

Along with the above considerations, the power supply must operate below its maximum rated output current. Loads drawing more current than the adapter is rated for can cause inconsistent results or device malfunction. Overloading the converter can lead to overheating and ultimately failure, potentially causing a fire hazard or damaging the load itself.

Important Specifications

While all power supply specifications are valuable, some are more critical than others. A few specifications of note are:

Output Current: The maximum current that can be supplied to the load.

Load Regulation: The load regulation is how well the regulator can maintain its output with a load current change, and usually is measured in millivolts (mV) or as a maximum output voltage.

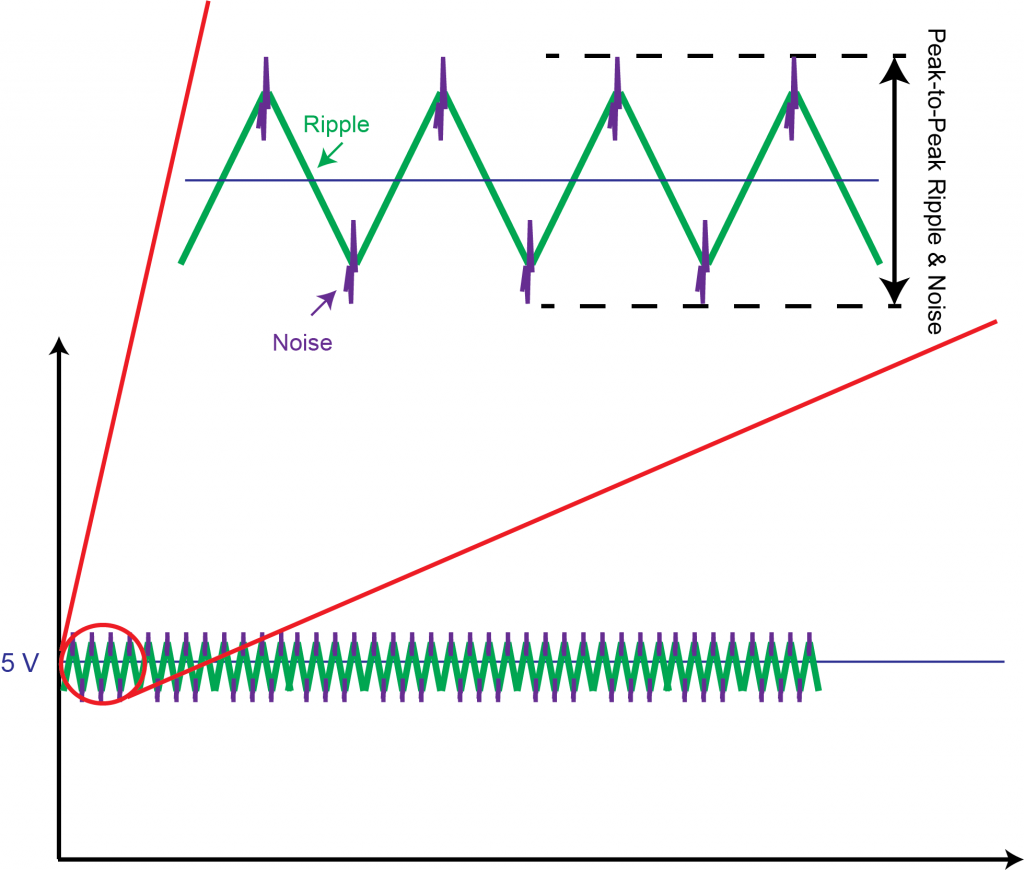

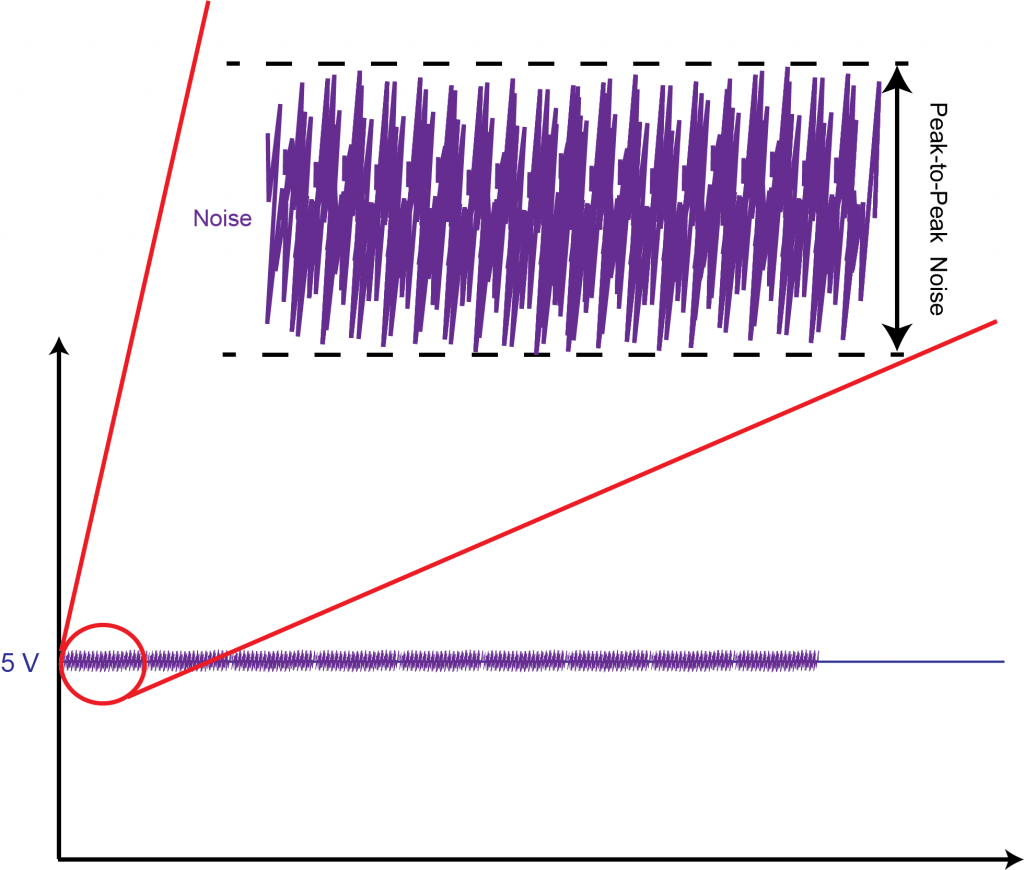

Noise & Ripple: Noise is any added and unwanted electronic interference, and ripple is the small variation in voltage when AC is transformed into DC. These are typically combined into one measurement. In switching power supplies, the measurement is given in peak-to-peak, showing the extent of the noise spikes that arise from the switching.

Overvoltage Protection: Sometimes output voltages can exceed their nominal values and can damage the load. Overvoltage protection is a circuit that shuts down the power supply should the voltage limits be exceeded.

Overload Protection: Overload protection is a safety measure used to prevent damage in the event of a short circuit or overcurrent event. Much like the circuit breaker in a house, the overload protection shuts off the power supply so the load will not be damaged.

Efficiency: Efficiency is the ratio of power being pulled from the power grid that is effectively being converted to DC power. A good SMPS power supply will operate with at least 80% efficiency and, with a proper system design, can operate at even higher rates. An efficient system will reduce heat generation and can save energy.

Noise & Ripple

Noise and ripple are artifacts of the transformation of AC to DC and are the byproduct of rectification and switching. During conversion, the alternating sine wave cannot be completely suppressed. These artifacts are typically combined into one specification, given in peak-to-peak voltage, showing the extent of the noise spikes that arise from switching, which can negatively affect sensitive instrumentation.

The small voltage variations are called ripple. Many times, the amount of fluctuation depends on how well the power supply is matched to the load.

Noise is the unwanted additions that occur outside of the normal ripple. It comes from many other sources, including switching and electronic noise generated outside of the power supply, such as from nearby electronics. Noise usually occurs in conjunction with ripple and is much more variable and unpredictable. Switching noise typically occurs at very high frequencies.

Figure 7 is an example of noise (created by switching) and ripple in a medium quality power supply.

Figure 7: Ripple & Noise for Regulated, Switched Power, Representative of a Mid-Quality Supply

Figure 8 illustrates the noise potential in a regulated linear power supply. While much less than the ripple of a regulated switched supply, it can still be significant enough to mask data. If the noise and ripple are very high, small signals can be overwhelmed or the life of the hardware can be significantly shortened. However, with a high quality power supply it can be virtually eliminated.

Figure 8: Ripple & Noise for Regulated, Linear Power, Representative of a Mid-Quality Supply

Frequently Asked Questions

- How much current does my power supply need?

A good rule of thumb is to combine the amount of drive current needed to meet the needs of the load and the current needed to power the controllers, and then add 10% as a buffer. - Can I use the same power supply to drive my temperature and laser controllers?

Yes, as long as the voltage selected meets the needs of the load and is within the Safe Operating Area (SOA) of the controller, and the laser, thermoelectric, and temperature sensor are not electrically tied through ground.

For more information on SOA, see Application Note AN-LDTC01: The Principle of the Safe Operating Area.

For more information on grounding, see Application Note AN-LD16: Grounding with Special Laser Diode Configurations. - Can I use the same power supply to drive several temperature controllers at the same time?

Yes, but they should be connected using star (individual) connections rather than serial (linked) connections to ensure that the voltage to each unit is the same. - Can I use a 30 V power supply with a temperature controller whose specifications are for 5 V – 30 V?

Yes, if the load voltage is high enough. Use the Safe Operating Area (SOA) calculator for the controller to determine if the load and the power supply voltage are compatible. - Can I use a 4.5 V power supply?

Review the minimum specifications for the controller in the “Absolute Maximums” section of the datasheet. If allowed, subtract the compliance voltage drop across the controller from 4.5 V to see if there will be enough voltage to the load. - How long should my cables be?

Longer cables introduce more noise and allow for more voltage drop between the power source and the load. To minimize the affects of noise, twist the cables together or use shielded cables. To help minimize voltage drop, keep them as short as possible. - What gauge wire should I use?

The gauge determines the current carrying capacity and needs to exceed the specification of the load. For example, using Table 2, which shows some standard gauges and carrying capacities for solid wire, a 20 gauge wire, not a 22 gauge wire, would be required for a load of 2 A. This is because the 20 gauge wire allows a 3.2 A current, which exceeds the 2 A requirement.

| AWG GAUGE | DIAMETER (inches) | ALLOWABLE CURRENT (A) | RESISTANCE per 1000 ft2 (Ω) |

|---|---|---|---|

| 8 | 0.128 | 50 | 0.628 |

| 10 | 0.102 | 30 | 0.999 |

| 12 | 0.081 | 25 | 1.588 |

| 14 | 0.064 | 20 | 2.525 |

| 16 | 0.051 | 10 | 4.016 |

| 18 | 0.040 | 5 | 6.385 |

| 20 | 0.032 | 3.2 | 10.15 |

| 22 | 0.025 | 2.0 | 16.14 |

| 24 | 0.020 | 1.25 | 25.67 |

| 26 | 0.016 | 0.80 | 40.81 |

| 28 | 0.013 | 0.53 | 64.90 |

| 30 | 0.010 | 0.31 | 103.2 |

NOTE: resistance is measured at 20°:C.

Table 2: American Wire Gauge (AWG) for Solid Wire

A Little History

At the advent of electrical distribution, the standard current in Europe was alternating current (AC) and in the US was direct current (DC). The main load of electrical usage was the light bulb, which was designed by Thomas A. Edison to use direct current. The early competition between which electrical distribution system would dominate the market in the US was called The War of Currents and was typically personified as a conflict between inventor Edison (Con Edison/General Electric) and entrepreneur George Westinghouse (Westinghouse Electric), who invested in the AC technology as a power distribution method. The conflict was actually much larger, with American and European companies having a vested interest in the decline of one type or the other.

The drawback of alternating current at the time was that load on the system was affected when appliances were turned on and off, affecting others using the line. Direct current had the advantage of using only the current needed and not affecting the rest of the load on the line.

Unfortunately for the DC proponents, the voltage drop across the wires from source to output was significant and different voltages could not be sent across the same wires. This meant that DC generation required generating plants to be located within about a few miles of their destination and multiple wires strung for each voltage needed, both of which were prohibitively expensive for rural communities. A further disadvantage was that DC was really only feasible for small appliances, as the low voltages were too inefficient to be scaled up for technology that required large voltages.

In contrast, high voltages of alternating current could be transmitted very long distances on a single line, for hundreds of miles and therefore required fewer generating plants. Transmission of AC resulted in very little voltage drop, and the voltage could then be reduced through the use of transformers to the desired amount needed at its destination. Additionally, with increasing industrialization, the high voltages were desirable for large loads, such as railways and industrial motors.

Competition remained between AC and DC proponents until a series of events, contract awards, and field trials proved that AC transmission lines were the most economical, although DC lines remained in use well into the 20th Century. Since most appliances, developed by Edison, were DC devices, the need for direct current was strong. Since AC could be stepped down to any DC voltage, DC systems are still utilized.