We know how challenging things are right now and hope you and yours are safe.

We at Wavelength are following CDC recommendations to actively encourage sick employees to stay home, educating employees on proper respiratory etiquette and hand hygiene, and appropriately cleaning the workplace.

We are checking temperatures, following social distancing protocols, and wearing masks in the factory. Our China distributor, Photonteck, kindly donated numerous face masks for our employees.

Designated as critical infrastructure, we have and will maintain customer service, engineering, and manufacturing operations. We have explored the risk of suppliers in affected areas and have increased our purchases as needed to ensure continuous flow of product. There are no problem items to report as of today. As this is an evolving issue, Wavelength will issue statements as conditions change.

Stay safe out there.

Subscribe to our newsletter for tips, techniques & product updates.

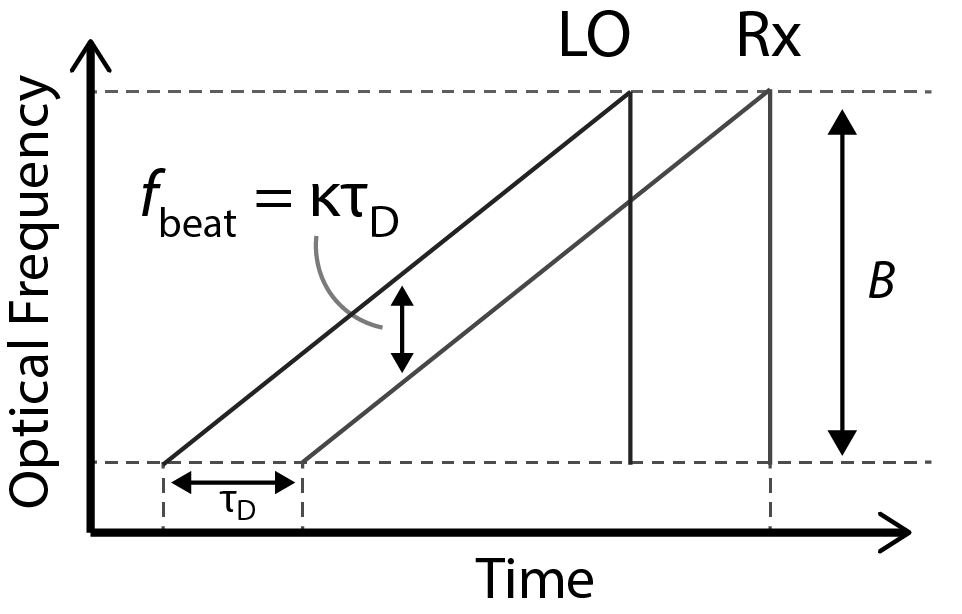

When manufacturing optics, confirming that they meet specifications is critical. Typical thickness measurement methods tend to use contact systems that damage the optic. Typical non-contact metrology techniques use methods that have problems with surfaces that diffuse the light. Bridger Photonics provides a non-contact solution for both thickness and length measurement with a Frequency Modulated Continuous Wave (FMCW) Light Detection and Ranging (LiDAR) technique utilizing Wavelength Electronics’ WTCP temperature controller. Without contact with the optic, Bridger Photonics can measure lengths of up to 2 m and thicknesses of up to 60 mm with 1 μm precision. The FMCW LiDAR Metrology Systems provide additional benefits including three dimensional (3D) mapping with the precision and accuracy needed in laser materials processing applications and optics manufacturing. Read more here.

Reduce COGS with a Product Variation

Wavelength can reduce cost of goods (COGS) by building standard product to a customer’s specification. For example, providing the unit without the final cover or cables, with connectors instead of terminal strips, or using fixed resistors instead of potentiometers.

When a lower power laser diode must be upgraded to higher power, we can often modify an existing product to meet the increased current requirements, so the control PCB does not need to change. We can also install the electronics on custom baseplates.

We accommodate these requests through the Product Variation system. You will be assigned a Product Variation number of the form PV###. The PV number will show on the sales order along with the standard product number. We develop an Assembly / Test document that details what needs to be different. This travels with the order through processing. The final product is engraved or labeled with the PV number and the lot number.

We manufacture the products in house, so we have complete control over quality and schedule. If you’d like to streamline your assembly time or reduce system COGS, contact our Applications Engineers.

Both the PLD-CH and LDxCHA Series laser diode drivers provide excellent laser control and can be paired with the PTC-CH Series temperature controllers. The LDxCHA is an advanced design using state of the art technology. It has lower noise, higher bandwidth and more output current.

| LDxCHA Series | PLD-CH Series | |

|

|

Output current limit functionality varies substantially between the PLD-CH and the LDxCHA. When current goes into limit, the PLD disables output current while the LDxCHA clamps the current at limit and keeps output flowing to the laser diode. The LDxCHA also includes a current setpoint monitor, so that you can set the setpoint before enabling current to the laser diode. The LDxCHA output current monitor is more accurate. The PLD-CH and LDxCHA Analog Inputs can add to the setpoint, while the LDxCHA can also subtract from it.

Our Application Engineers would be happy to assist you in determining which is best suited to your application.

We invite you to contribute topic suggestions, questions, and general feedback. Wavelength will incorporate as much reader input as possible.

Click to Submit