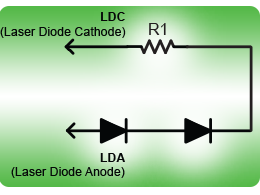

Wavelength suggests using test loads for initial setup of a laser diode driver and sometimes a temperature controller. Using a test load, you can gain confidence about how the controller works, gauge the sensitivity of the potentiometers, and learn how to monitor the output and use transfer functions. Using a test load creates predictable results. If something isn’t working in your system, removing the load and using a test load isolates the problem to the controller or the load or power supply. To use a test load with a laser diode system, you first run in Constant Current mode. If you also want to check the photodiode feedback circuit, you can set up a Constant Power test load. Wavelength suggests test loads for each product family in each datasheet. We also have developed an Application Note detailing how to use the test loads. AN-LDTC04: Test Load Basics.

Subscribe to our newsletter for tips, techniques & product updates.

We’ll be in San Francisco February 4-6 at South Hall, Booth 2134. You can meet our new sales engineer, Joe McDonald, or make an appointment to discuss your application with an engineer. We enjoy meeting with you face-to-face and hearing about the new developments in your work. If you need a free entry pass, just let your account manager know. We are showcasing the new PWM temperature control component – the WTCP. Improvements have been made to the patented low-noise QCL driver. We’ve also formally renewed the CE Mark on both the PLD laser diode drivers and the PTC temperature controllers. If you need any of our products in a different form factor, or with a different set of features, this is an excellent opportunity to discuss those details. Drop by and mention this newsletter to receive a special gift. To contact your sales engineer, email Sales@teamWavelength.com. We look forward to seeing you there!

A Tip to Increase Temperature Stability

I want to optimize temperature stability, what can I do with the sensor?

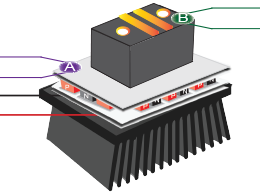

Sensor placement is critical. If you place the temperature sensor close to the device under control (B), it will read an accurate temperature. If, however, this puts it a distance from the actuator (Thermoelectric or Resistive Heater), there will be a thermal delay in the sensor feedback that will decrease temperature stability. For example, the more accurate system usually uses a smaller Proportional Gain (P) and an large Integrator Time Constant of 5-10 seconds. The more stable system (A), with the sensor placed closer to the thermoelectric is stable over a wide range of Proportional Gain settings and uses a small Integrator Time Constant of about one second. With this system, you have the freedom to increase the Proportional Gain to reduce time to temperature. Wavelength engineers have helped clients optimize system performance for over 20 years. Feel free to leverage our experience to troubleshoot any part of your system.

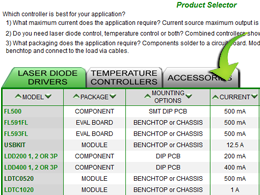

How do I choose the right controller for my project?

For a laser diode driver, start with the current and voltage requirements of your laser diode. For Wavelength components, Maximum Output Current is a field in the Product Selection Guide that you can sort on. Narrow your choice first by current. Compliance Voltage is the maximum voltage that can develop over the laser diode at maximum current. Make sure you choose a driver with high enough compliance voltage – especially if you are driving multiple diodes in series or bars. Next, decide whether you want a component without moving parts that installs on a PCB or an enclosed controller with on-board trimpots and indicators that mounts to a chassis. Again, the Selection Guide can be sorted by Package – PCB Mount or Chassis Mount. Modulation bandwidth and noise are typically the next most important specifications. These can be found in the OVERVIEW and SPECIFICATIONS tab of the product web page or in the datasheet. As always, if you have questions, call (406) 587-4910 or email techsupport@teamWavelength.com.

We invite you to contribute topic suggestions, questions, and general feedback. Wavelength will incorporate as much reader input as possible.

Click to Submit